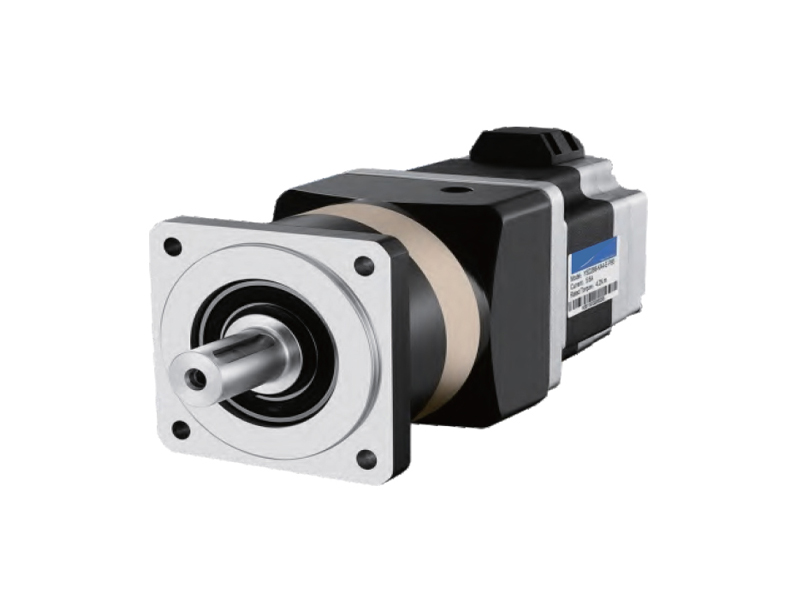

The combination of a two-phase closed-loop stepper motor and a planetary gearbox is a common approach, which can fully utilize the advantages of stepper motors and planetary gearboxes to achieve precise and efficient motion control. The following is a detailed analysis of this configuration:

1、 Combination advantage

High precision positioning: The two-phase closed-loop stepper motor itself has the ability of high-precision positioning. By combining with the planetary reducer, the positioning accuracy of the system can be further improved. The planetary reducer ensures the accuracy of output motion through its precise gear ratio.

Increasing torque: Planetary reducers can amplify the output torque of stepper motors, enabling them to drive larger loads. This is particularly important for applications that require high torque drive.

Reduce speed: The planetary reducer can reduce the output speed of the stepper motor to meet the working requirements of low speed and high torque. This is a very important characteristic for some precision mechanical equipment.

Improving system stability: The use of planetary reducers can reduce the vibration and noise of stepper motors during high-speed operation, improving the stability and reliability of the entire system.

2、 Configuration points

Compatibility: It is necessary to ensure that the output shaft diameter of the stepper motor matches the input shaft diameter of the planetary reducer. If there is no match, a transition shaft or coupling needs to be used for connection. Meanwhile, it is also necessary to pay attention to the axial and radial compensation methods to ensure stable and reliable connection between the motor and the reducer.

Reduction ratio selection: Choose the appropriate reduction ratio according to the application requirements. The choice of reduction ratio will directly affect the output speed and torque of the system. If high-precision and stable speed control is required, it is necessary to choose an appropriate reduction ratio and pay attention to whether the torque and speed response of the motor meet the application requirements.

Load bearing capacity: The load bearing capacity of the planetary gearbox needs to be considered. If you need to drive a large load, you need to choose a planetary gearbox with a larger output torque.

Efficiency and service life: It is necessary to confirm the efficiency and service life of the planetary reducer to ensure the stability and reliability of the entire system. Efficient planetary reducers can reduce energy loss and improve the overall performance of the system; And a longer service life can reduce maintenance costs and improve the economy of the system.

English

English Russian

Russian Spanish

Spanish Italian

Italian Arabic

Arabic Korean

Korean German

German Japanese

Japanese Vietnamese

Vietnamese Turkish

Turkish

Introduction

Introduction Specification Table

Specification Table Download

Download